- Our product cycle

Topstar brings together all the important processes for manufacturing a product under one roof. Product design, product concept, product construction, series production, test laboratory and quality control. We want products that last as long as possible, which is why we avoid short-lived trends. This can be seen above all in our classics (Topstar: OpenPoint; Wagner: AluMedic). Sustainable product design/development is a time-consuming topic – for this reason, we take our time and attach great importance to a holistic and sustainable process. One of our major goals is to try to design products from a “cradle to cradle” perspective in order to enable materials to be recycled. This means that a product that is no longer needed does not become waste, but provides the raw materials for a new product. We take this basis into account in product development, and it should become an essential part of it.

The individual aspects of our product cycle are described in detail in the following process.

- A1. Design and development center

New product ideas and technical innovations are constantly being developed in our in-house design and development center. Existing models are also constantly being developed further and protected by active patent and utility model management. Thanks to the central value creation at the Langenneufnach site, close coordination with quality assurance, sales and other key areas is guaranteed at all times – so market requirements flow directly into development.

An established process is FDM printing in our in-house model making department, which we use to produce prototypes quickly and in a resource-saving manner using biodegradable GreenTEC material. This comes from 100% renewable raw materials and offers an environmentally friendly alternative to conventional plastics.

- A2. Procurement

We have been pursuing the goal of ensuring sustainability along the entire value chain for years. Thanks to the close exchange with our main suppliers, we are always informed about developments and challenges. Our Code of Conduct also applies to procurement management – we expect our partners to comply with environmental, social and ethical standards.

As part of legal requirements for transparency in the supply chain, we are continuously working on a more in-depth information base and are currently developing guidelines for sustainable procurement. When selecting materials, the focus is on quality, safety and sustainability – we check the suitability of materials in terms of these aspects as early as the development phase.

In particular, the use and recycling of plastics plays a key role: many non-load-bearing components are already made from recycled material, which we are constantly expanding in collaboration with our suppliers. We also pay attention to sustainability when it comes to upholstery fabrics – almost all of them are certified to Oeko-Tex Standard 100.

For quality assurance, our products are GS-tested according to the modular principle. Close cooperation with experienced designers and developers ensures that we combine the highest standards of function, design and sustainability in every product.

- A3. Incoming goods and quality assurance

All supplied parts undergo a comprehensive quality check upon receipt. Thanks to clear coding, the entire storage, production and shipping process can be traced transparently. We continuously optimize products and logistics in close cooperation with our suppliers. For example, reusable mesh boxes were introduced and packaging was checked for efficiency and resource conservation. The proportion of plastic in cardboard packaging has been further reduced by using recycled packaging padding.

- A4. Production

Our two modern production lines enable us to manufacture up to 10,000 chairs a day – as partially disassembled cardboard goods or fully assembled by specialized logistics partners. Individually configured models are also produced to customer specifications. Each product is given a serial number before the start of production for clear allocation and complete traceability. Comprehensive quality controls ensure product quality during production. In addition, all components and models are tested to the highest standards in the company’s own test laboratory.

- A5. Sales

Sales forms the interface between the company and its customers – it communicates our philosophy to the outside world and customer wishes to the company. These clearly show that sustainability, resource conservation and climate friendliness are key concerns. That is why we integrate these requirements into products, processes and logistics in a targeted manner.

- A6. Shipping

Partly dismantled, carton-packed goods are assigned to orders, transported, sorted and picked fully automatically. Fully assembled chairs are delivered directly by a specialized logistics company with minimal packaging – this allows up to 25% more chairs to be transported per delivery and significantly reduces emissions. Through ongoing process optimization, we avoid unnecessary subsequent deliveries and reduce the use of resources, e.g. by switching to a new, low-waste stretch film at the end of 2024.

- A7. Retail Trade

Our products are sold in over 50 countries worldwide – in collaboration with a wide range of retail partners. They play a key role in passing on our mission of active, healthy sitting to our customers. Regular training courses on products, materials and workplace design are a matter of course for our partners and sales staff. Ongoing investment and continuous product innovations strengthen our competitiveness.

- A8. Product usage

From the idea to series production, the focus is on the long-lasting and sustainable use of our products – on a par with ergonomics and design. Our chairs are designed for an above-average service life and are manufactured using the resource-saving modular principle. This allows for easy repairs, adjustments and extensions. We also guarantee that all our products are safe and free from harmful substances.

- A9. Disposal recommendation

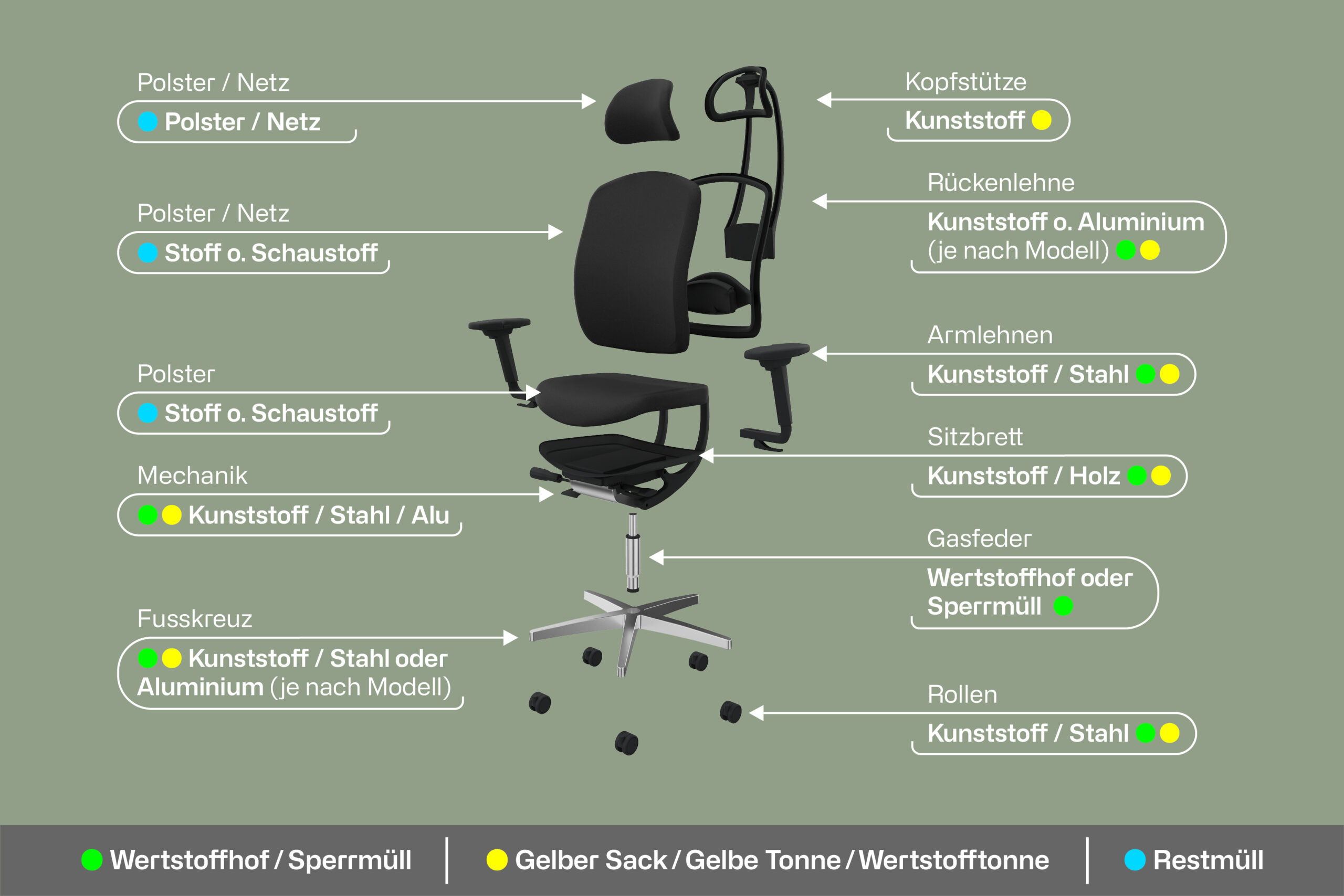

To support the environmentally friendly disposal of our products, we provide our customers with clear recommendations. Our infographic shows at a glance how to correctly separate and dispose of the individual components – be it via the recycling center or bulky waste, the yellow bag, the yellow or recycling garbage can or in the residual waste. In this way, together we can help to conserve valuable resources and promote recycling cycles. We will explain to you how to dispose of it properly if the model can no longer be repaired.

- Recycling center/bulky waste

Large parts such as backrest, steel or aluminum parts, gas spring, wooden seat boards.

- Plastics and packaging

The disposal of plastic parts depends on the local waste regulations. Please contact your local waste disposal company for more information.

• Yellow Bag / Yellow Garbage can: Packaging such as milk cartons, possibly cans (depending on the municipality)

• Recycling garbage can: Also household items made of plastic or metal

- Incoming goods and quality assurance

Non-recyclable waste such as fabric scraps and foam materials belong in the residual waste garbage can.

- The other pillars of our sustainability strategy:

Climate & Resources

Work & Future

Do you have a question about our sustainability? – Don’t worry, we’re here to help you. Feel free to contact us at any time.

Contact details:

Sustainability Manager

Mrs. Sabrina Portner

TOPSTAR GMBH

Augsburger Str. 29, 86863 Langenneufnach

Phone: +49 (0) 8239/ 789 0